A WorkSafe – Energy Safety prosecution of an electrical worker has created a large amount of interest among industry professionals.

While the case is awaiting sentencing and WorkSafe is limited in how much we can say, we appreciate those in the industry would like to know what the issue was with the installation which caused a person to be electrocuted and want to take the opportunity to share this information.

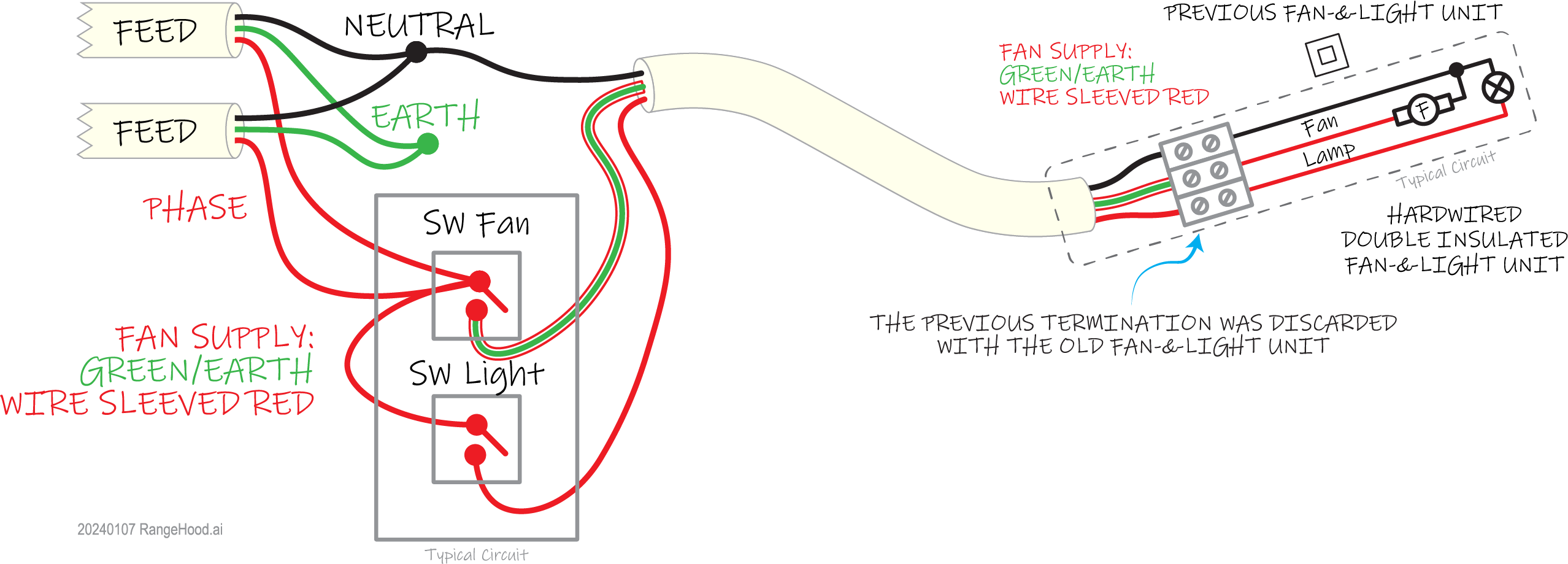

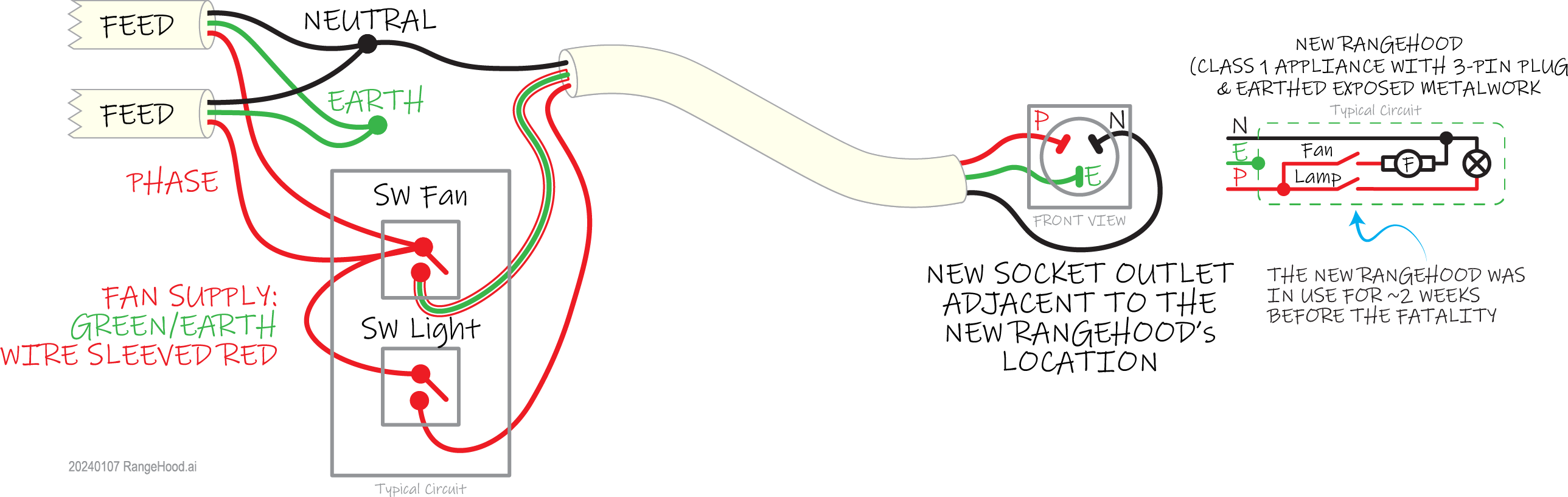

An electrical worker was engaged to replace a permanently connected kitchen extraction fan and light unit with a new rangehood. A new socket-outlet would be required and need to be installed to supply the new rangehood. The existing unit was removed and the electrical worker, in cutting the cable, failed to observe that the green earth conductor was being used as a second active to supply the fan in the unit.

In the past, it was not uncommon for a green earth conductor to be sleeved red and used as a second active conductor. This was the case with the existing unit, where it was using an active for the fan, an active for the lights, and a black supplying the neutral.

The diagrams below show what happened very clearly.

The electrical worker supplied certification to the property owner which contained a declaration that the installation of the socket-outlet was connected to a power supply and safe to use.

As part of WorkSafe’s investigation it was identified that the electrical worker had failed to adequately test and verify the installation as required by AS/NZS 3000:2007.

It is a mandatory requirement to test all prescribed electrical work on an installation for operational safety and to ensure the installation is safe to use.

If the requisite testing had been carried out, the electrical worker would have identified that the earth conductor was connected to the wall switch and was previously being used as a second active. The connection in Figure 2 would have failed testing and verification as required by AS/NZS 3000.

Ten days later another contractor was engaged by the property owner to install a flashing around the rangehood and in doing so he received a fatal electric shock. There has been some conjecture as to why users, who may have been using the rangehood in the corresponding period, had not received an electric shock. There was no evidence from the WorkSafe investigation that the users came into contact with the exposed conductive parts of the rangehood. The contractor, in installing the flashing, did make contact with the exposed conductive parts.

There have also been suggestions that the contractor removed or interfered with the electrical work in some way. The evidence gained during the investigation determined that neither the contractor or anyone else removed, altered, or otherwise adapted any electrical cabling, switches or similar.

This is a reminder for all electrical workers that not carrying out the required prescribed testing and verification will create a significant risk that a person will suffer serious harm. In this case it would have prevented a tragic event where a person lost their life.

Paul Kauder, Technical Officer, WorkSafe – Energy Safety.