In the previous article the selection of motor isolators was discussed. In this article we give details on the process for selecting a machine main switch, for which there are some key differences.

Standards exist that stipulate requirements for machine safety and the criteria that main switches must meet in order to safely disconnect a machine from the supply when required. Relevant standards include the likes of IEC60204-1 and AS/NZS 4024.1204.

There are several types of acceptable supply disconnecting devices. Top of the list are “Switch-disconnectors” otherwise known as an “On-Load Isolators”, which are a practical and economic solution, just as they are for individual motors and other loads. As with a motor isolator, a main switch must be rated to utilization category AC-23 or DC-23 ensuring it can make and break the load under severe conditions. Refer previous article “Isolator Selection Made Easy” for further explanation and details about utilisation categories.

The difference with a machine application compared to a single motor application is that a machine may have several motors of different sizes, associated switchgear, monitoring and control equipment, lighting and HMI. The standards recognize this mixed load with machines, and the main switch shall be rated to carry the full thermal load (Amps) of the entire machine and also have an AC-23 rating in case of locked rotor fault conditions of the single largest motor.

Machine Main Switch Selection

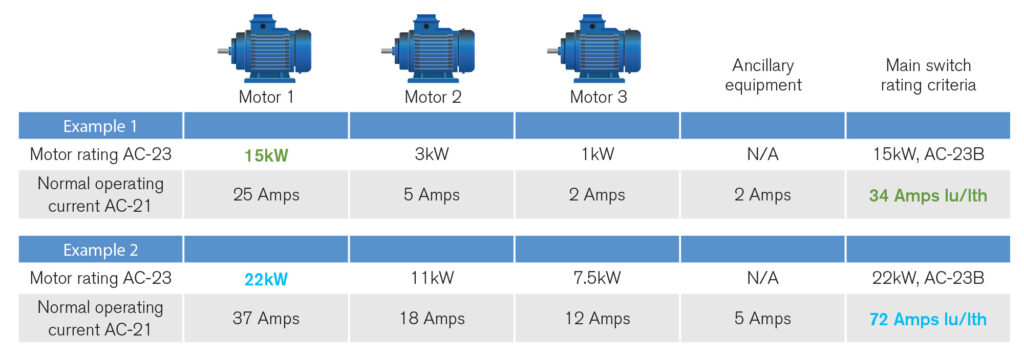

In the examples below the largest motor and the total combined load in Amps for each machine have been highlighted for your reference.

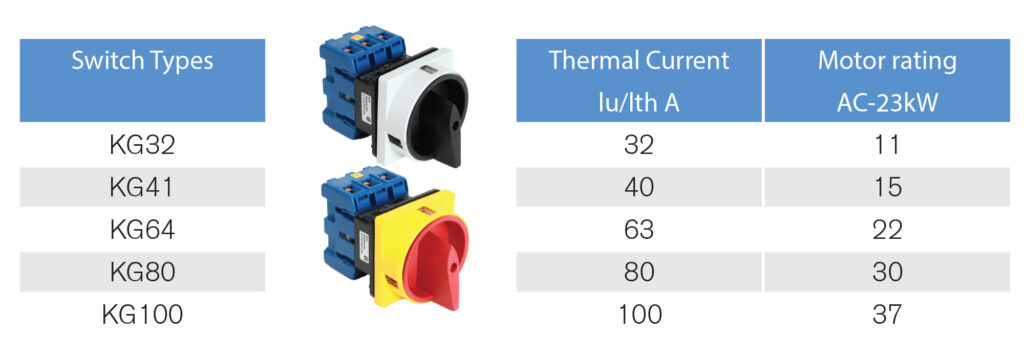

Switch Rating Table

Example 1

The largest motor is 15kW AC-23 and the total normal operating current is 34 Amps. A suitable main switch from the Kraus & Naimer range would be the KG41 rated at 15kW AC-23A and 40 Amps thermal.

Example 2

The largest motor is 22kW AC-23 and the total normal operating current is 72 Amps. From the Kraus & Naimer range a KG64 switch is rated at 22kW AC-23 catering for the largest motor. However, the total thermal load of 72 Amps is above the 63 Amp thermal rating of the KG64 so it cannot meet both requirements of this machine. The next size switch is a KG80 rated at 80 Amps thermal and 30kW AC-23 which would fulfil both requirements and be selected. (see rating table above)

Switch handle colours

The machinery standards also stipulate the use of particular handle colours to avoid confusion when an emergency shutdown is required.

Where the main switch is intended for emergency use (anywhere it is foreseen they could be used in an emergency situation) the main switch shall have a red handle and a yellow background as with all emergency stop devices.

Where the main switch is not intended for emergency use the handle colour is recommended to be black or grey to avoid confusion.

Main switches shall also have an appropriate degree of protection (IP rating in accordance with IEC 60529) against the effects of liquids, vapours or gasses found in the physical environment or used on the machine as well as protection from the ingress of contaminants e.g. swarf, dust or particulate matter.

Door interlocks for cabinets

When there are control cabinets on machines a door interlock is required to ensure the cabinet cannot be opened when equipment is live. Door interlocks are available for main switches to achieve this.

Where access to the cabinet is required when equipment is live, there are a range of interlocks readily available to enable authorised personnel to defeat the interlock and gain access.

This article is an insight to machine isolation by main switches and does not intend to cover all aspects of machine safety. Please contact your main switch supplier for further details on available products and their features.

Disclaimer: The information in this article represents only part of the machinery safety standard requirements. When working to standards you should always reference the actual documents and they should be read in their entirety.